The importance of product features to construction companies.

Construction is viewed by many as a complicated business, but the exciting part is that it is not. If you look at it from a business perspective, it is an excellent venture, just like any other business. However, anybody planning to invest in a construction company must understand the characteristics of a product since they play a significant role in the market positioning. But this can only be achieved by understanding the construction features. These characteristics describe what a product is made of, its work, and how it does it. The product features may include tools used, color, size, and shape. These are the essential features that customers check when buying a product.

Different product features serve the customers differently. In simple terms, customers prefer one product to the other based on the distinction of their features. Therefore, any construction business should ensure its products have unique features that meet customer expectations differently. To do this, construction managers should identify the customers’ unique needs and develop a product that best meets them.

The construction business has been very competitive, and companies are investing heavily to remain relevant in the market. It is essential that general contractors clearly understand the customer needs and adopt the best approach to save time and stay profitable. This can be done by introducing new products or improving the existing products. Contractors can develop new innovative ways of constructing unique products that meet the customers’ needs differently to remain competitive in the market. Alternatively, contractors can add more features to existing products to make them better and match the changing customer needs.

Product Features of a Building Product

This refers to the characteristics of a building, e.g., height, materials, and floors, among other things. Product features communicate the product value to potential customers. For example, a sturdy structure made of durable materials and an attractive artistic design can be more appealing to customers than those made of typical designs. It’s essential to carefully define the construction product features ensuring that they meet the required standards and address the customer needs adequately.

Product Features of Road Construction Product

Just as the features of house construction, road construction products describe the road, its features, and how it works. The elements may include materials, designs, texture, dimensions, and load capacity, among other features. These features similarly define the value of this product. For example, a road made of solid tools and safety standards attracts more buyers than one made of low-quality materials and has a low load capacity. It’s essential to define the product clearly to attract the right customers.

Product features can also help attract customers looking for a specific product. For example, suppose a customer requires a road built with particular tools and features. In that case, any other product that doesn’t meet these specifications cannot attract such a customer.

When defining the product features, construction firms must ensure that the tools used conform to all the quality checks and safety measures to meet the intended application by the potential users.

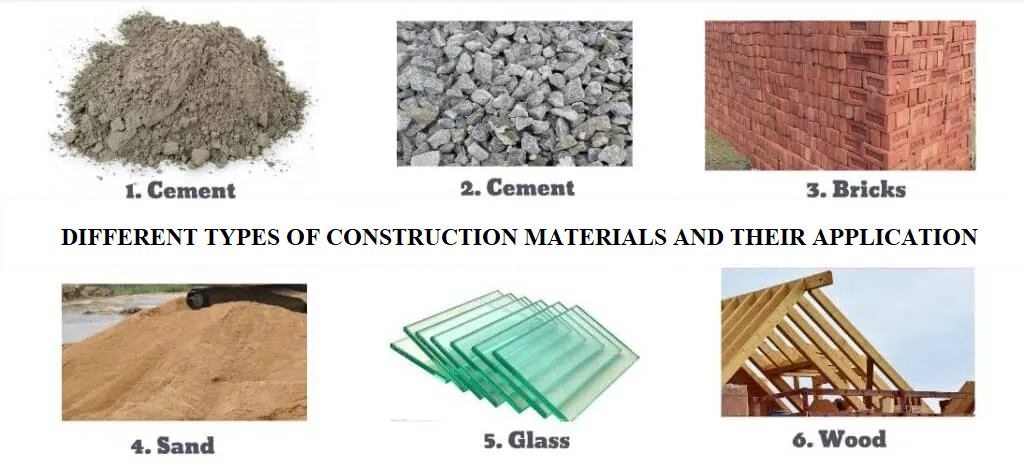

Necessary materials in a construction product

When doing construction work, it’s essential to consider product characteristics since this is what determines product quality. For instance, customers looking for durable construction products may prefer a house made of concrete instead of a wooden one. Other construction materials may include glass, wood, concrete, steel, etc.

However, wood may provide the best material for making furniture, windows, floor, tiles, and fittings. On the other hand, steel may be good for constructing things like gates, windows, structural beams, and foundation pillars.

Plastic is suitable for creating electrical conduits and pipes. It can also be used in the construction industry to make binders in asphalt since it provides a smooth surface on which vehicles can travel. It can also be used as a seal to prevent drainage leakage.

To sum it up, manufacturing companies in the construction industry should always ensure that the best features are used through the various stages of construction. There is a need to engage several subcontractors through the development phases to ensure that everything is done to the required standards. All the essential features should be implemented to give the customers the best quality.

There is a need to use recycled materials in road construction to minimize the environmental impact. Engineers and general contractors are adopting an innovative approach combining traditional materials with fibers to create more robust and durable road surfaces. For example, mixing asphalt and concrete with glass or carbon creates a more sustainable road network.

Engineers must keep exploring new innovative construction methods to improve performance, durability, and sustainability. Using more competitive strategies gives the business a competitive edge compared to its competitors.

How to develop product features

Understand the product

The first step in developing a product feature is understanding its purpose and the potential customer’s needs. This will help you identify the must-have features and tailor-make them to fit the customer demand. Next, you should identify the product’s unique selling points and determine every product feature’s importance to the users. This can help you differentiate your product from that of the competitors.

Develop the product features

After understanding the product’s purpose, it’s time to develop its features. The general contractor and the construction manager should engage other stakeholders and brainstorm to develop the best features that work in the best interest of the product users. It is essential to ensure that these features can work together to support the overall purpose of the product.

Testing of the product features

After this, it is vital to ensure that all the essential features work as required. This can be done through the use of simulations and prototypes. Software vendors have developed construction software solutions that can be used to run multiple projects. Proper testing of the product features ensures that the product is designed to meet the customer’s needs.

Feasibility test

Once you have understood the product features and the customer needs, you can cluster them based on their relative value. Prioritize the characteristics that give the best value for the customer without raising the allocated costs. Check the feasibility of each feature and adopt the ones that can be achieved in the shortest time to avoid production delays.

How to identify unique product features

The uniqueness of the product features gives the product a competitive advantage in the market. Contractors can adopt a construction management system that helps them identify customer needs and develop products to meet them. You can also engage directly with the customers, collect their views, and set the best features that meet their needs.

Developing unique product features requires a lot of creativity and engagement between different stakeholders in the construction business. Understanding the industry challenges provides room for innovation and the best way to address such gaps. To achieve this, the general contractor must conduct thorough research and collect data from other construction companies, customers, and other stakeholders in the industry. This helps identify potential challenges and adopt the most innovative approach to stay ahead of the competition.

linking construction product features to construction projects

Product features and construction projects go hand in hand. During project planning, the technical team specifies the tools required for the project’s completion. After identifying the features, the construction team should formulate a financial management plan that best meets all the project requirements. This involves creating purchase orders to acquire the necessary materials to meet customers’ needs.

The products must be procured in line with the management plans. All the products must meet the safety standards and the client’s requirements.

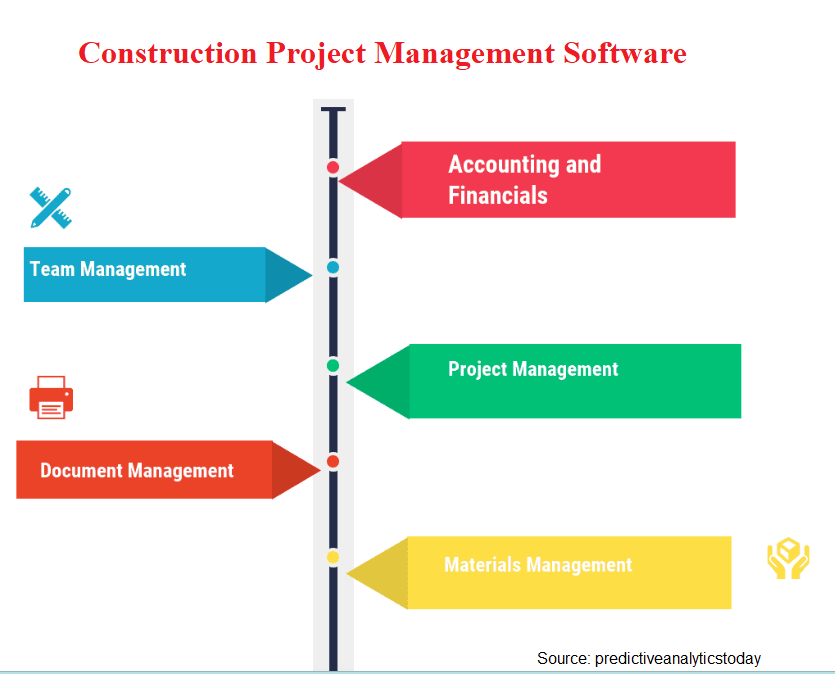

Using construction software to develop construction products

To achieve the best results, contractors can use construction project management software to achieve their goals effectively. Whatever purpose you want to achieve, there are numerous construction software features you can adopt.

CAD (Computer Aided Design) software

Examples of good project management software include simulation software, CAD software, and construction estimating software. Construction management firms use project management software to track the development of their products. A good construction management tool coordinates different teams and follows the product development process. It can also be used in construction project management to track and monitor development.

The construction industry can also use Computer Aided Design software to design and set the product’s dimensions, such as weight, shape, and materials, among other features of product plans. The CAD software can also test the product and make amendments to meet the customer’s requirements.

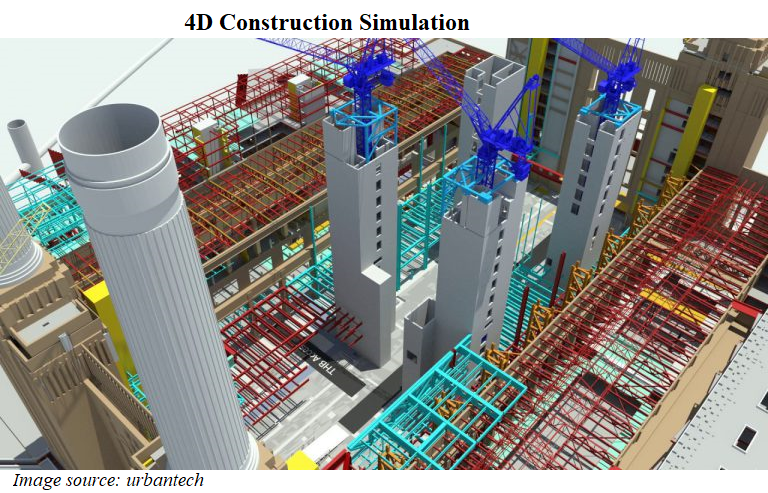

Simulation

Another construction project management software is Simulation which showcases the product’s performance in a real-life situation. The key characteristics are tested to ensure that they meet the project requirement. The simulation software also helps identify gaps and provides mitigation. By using the right construction management software, construction firms can adopt innovative approaches to achieve their goals effectively and avoid unnecessary costs.

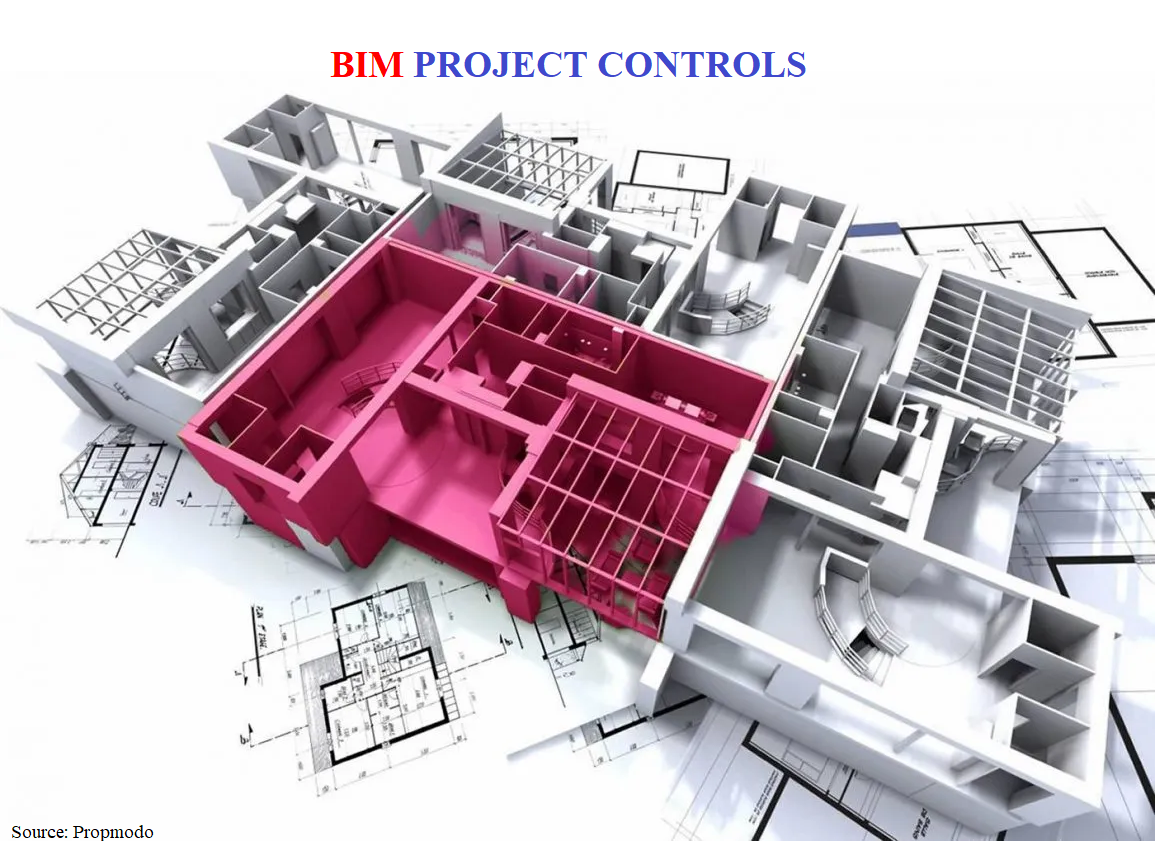

BIM (Building Information Modelling)

A construction company may also adopt BIM (Building Information Modelling) to create detailed modes of building features. These features can be used to simulate the product features in the real world. The BIM construction software then helps coordinate other stakeholders, e.g., engineers, contractors, architects, and other stakeholders.

The future of construction product features

It is hard to tell which product features will be the most preferred in construction in the future. Factors like government policies, change in customer preferences, and technology change, among other factors, determine the product features’ future. However, some product features may continue to dominate over others even amid the ever-changing technology.

Sustainability

Critical components like sustainability will remain relevant. There is a need to create environmentally friendly approaches in the construction industry. The use of recycled materials minimizes the environmental impact of construction activities.

Energy efficiency

Energy efficiency will also continue to trend due to the call for reducing energy consumption to reduce emissions. Products designed with energy efficiency will likely attract more demand than other products.

Automation

Automation is also another feature that is likely to trend. There is a need to develop innovative features that improve product performance and save costs. For instance, automated construction items are likely to reduce project completion time and improve productivity. Project management software such as CAD makes project management seamless and less costly.

Testing construction product features

Various methods of testing the construction product feature depend on the project’s needs. The most popular methods include Simulation, field testing, and lab testing.

In laboratory testing, samples of the construction product are tested in a controlled environment to determine their ability to meet the required standards—key features such as product strength, functionality, and performance, among others.

Field testing involves testing the product in the real world to ensure that the product meets the requirements. It also monitors the project to assess its reliability and durability.

Simulation involves using project management software to showcase the project’s performance in a real-world scenario. Key features like durability are checked here. The project manager must review the project’s key features to ensure it conforms with the construction project’s requirements.

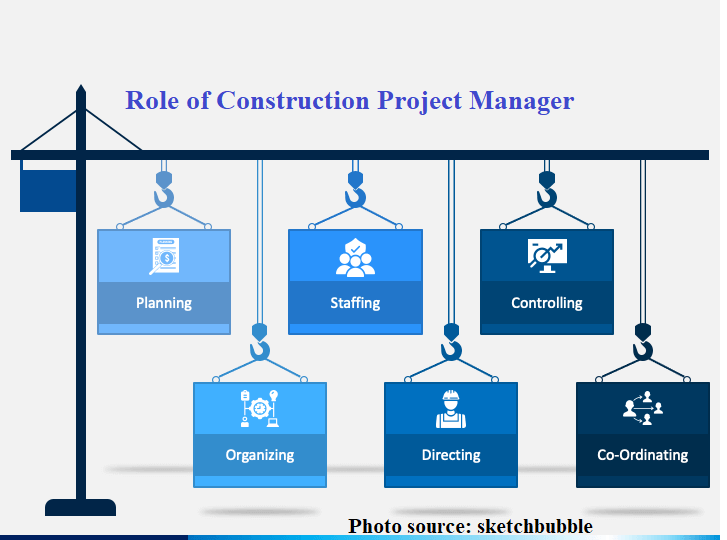

the role of construction project managers in product development

Project managers play a crucial role in product development. They are in charge of the whole project and oversee the entire product development process. A project manager is in charge of the following.

Setting the project needs and defining the key features of the construction project. Overseeing and coordinating the stakeholders throughout the product development process, providing progress reports, and making necessary updates.

Ensuring a smooth flow of the product development process to achieve the project objectives within the set timeframe and budget

Making any necessary amendments and improvements to ensure the product meets customer expectations

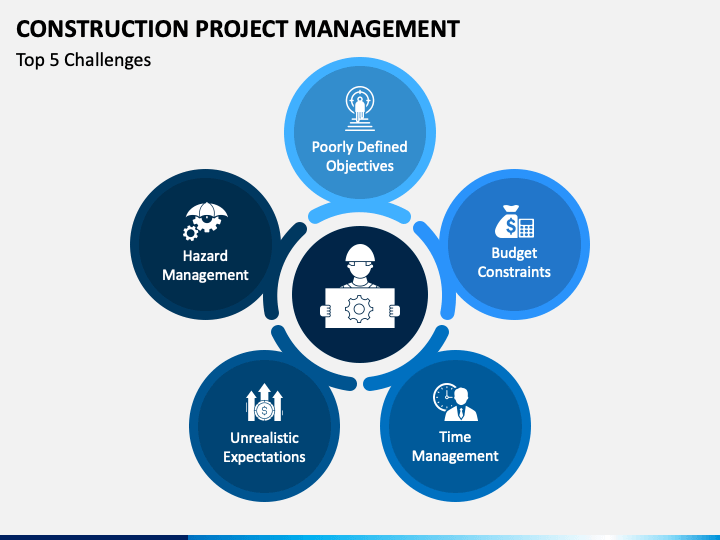

Top challenges facing construction.

Just like any other project, construction faces challenges.

Poorly defined goals

Any construction project must set goals to succeed. So, the construction management team must have clear goals that guide them throughout their operations. In addition, the stakeholders must understand all the tasks involved in the construction project and the expected outcomes.

Budget constraints

Every construction project follows a set budget with a clear allocation for each task. All the construction management operations must be guided by an explicit cash flow showing the available resources and their application. Therefore, Cost projections should be made accurately to avoid any construction delays. Different approaches can be used, both manual and automated, to ensure that all tasks are catered for. Poor budgeting may lead to project delays or a total halt.

Time management

Every project follows a set schedule from initiation to execution. All tasks are scheduled following the set timelines. You can use construction project management software to ensure that everything works as per the required time. To achieve this, all the work tools, equipment, documents, and other required tools should be at the job site in good time to avoid delays. The project’s progress can be affected if time is not managed appropriately.

Unrealistic expectations

Every construction project must follow clear guidelines. However, setting unrealistic expectations ruins the project delivery. It is vital that the construction management team set goals that are Simple, Measurable, Attainable, Realistic, and Time-bound. Since a lot of paperwork is involved in the construction industry, there should be easy access to different types of project documents for quick reference. This ensures that the stakeholders stick to the project goals.

Hazard management

Risk management is very crucial, both at the job sites and even at the product delivery. A construction management team that doesn’t take the point seriously may ruin the whole project. Customers must feel safe when using the product.

Conclusion

The construction project management team must understand the product features necessary throughout the project life cycle. Defining and understanding the project features helps the construction team achieve their objectives and seamlessly meet customer requirements. Construction project managers may use construction management software to create a sustainable product that meets customer demand.

You can achieve your construction project goals seamlessly with the Epiprodux tool. EpiProdux helps to understand what customers need and helps the stakeholders in project management to adopt the best approach that meets the customer demand and boosts profitability. Sign up today on Epiprodux and start your free trial